Our Manufactoring

At Glow, we are curious. We are women in STEM.

We get shivers when life experiences + opportunity + STEM = solving problems in new ways.

We partner with SUUCHI in New Jersey to make the magic. Through their proprietary software to manage product production to their network of manufacturers, we signed on with the Founder and CEO’s vision of how manufacturing will be led forward with technology in the United States (and abroad).

Suuchi Ramesh, SUUCHI’s founder and CEO spent 10 years in tech, with a background in software engineering. She believes that technology is the answer to reinventing manufacturing.

How is a product made?

A problem emerges.

“I’m tired of my butt showing while bending.” Or “nothing fits a size 4 waist with a size 8 boody and thighs” or “I’m 5’10” and nothing is long enough” or “I want more appropriate work clothes”

Teri, our designer, is an avid outdoorswoman, finding her joy on skis in the Wyoming mountains. She has spent a lot of time around snow and harsh wyoming weather. She has a career meeting folks in the fabric world, feeling those fabrics and putting them to work in designs she creates. She has designed for Simms (fishing waders), Mountain Hardware, Klim (motor / snow machine sports), and Black Diamond among others. Teri is our design godmother pushing us in the right direction.

Garment concept is chosen. Now it’s time to select fabrics. Our favorite part!

Fabric selection is magic. So many folks across the globe are creating great fabrics. They are pushing the limits on the old - with organic cottons, and wools. Fabric companies are blending synthetics and naturals to get the qualities of both, for example nylon = durable, and wool = breathable warmth. Recycled and renewable fabrics are coming online faster to keep up with demand. Repreve = recycled fiber, Hemp = able to be grown with zero pesticides or herbicides (guys, it’s literally a weed). Fabric science is an exciting frontier. 🤓

We go to Outdoor Retailer to feel and select fabrics. We ask questions like what are your minimum order requirements? What is your lead time for us to be able to get this? Some companies can’t accommodate small orders. They need orders of 10,000 yards or more (basically picture a yard per garment). Companies from across the globe come to the show - Europe, Asia and the United States.

We select a fabric and have it shipped to our pattern maker / prototype maker.

I know what you are thinking. Doesn’t the designer make the first sample? Not usually. This is another specialty. Some individuals are cross trained to do both.

Jerry in the Seattle area is our person. Jerry is your friend that “just likes to make cool shit”. He probably didn’t excel at classroom based learning. Jerry, we feel you. Sometimes we call and he is teaching himself how to make cabinets for a house he wants to flip. Other times we call and he is integrating electrical components into a heated jacket for another brand that he works for. Glow Workwear is in good hands.

Jerry finishes a prototype and ships it to Teri, then she sends it on to team Glow. And here begins the iteration process.

What part fits. What part doesn’t. Did we choose the right fabric. Does it fit in the crotch? (Lot’s of concern around the middle, crotch, butt area because we all want that to fit! We believe crotch is the technical term as we found no other reference words but are open to suggestion because that’s just sort of a weird word.)

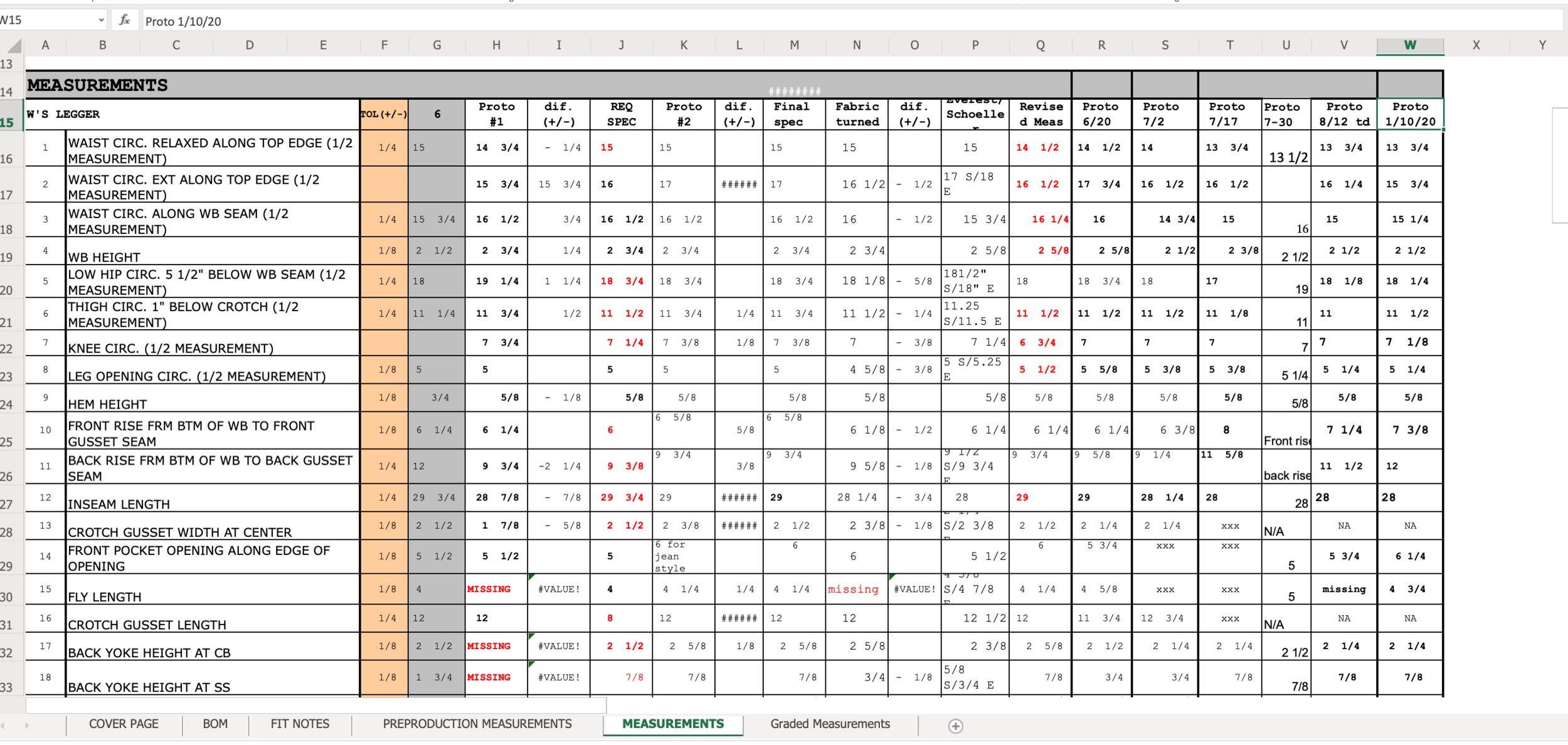

Product testing begins. We alter measurements to get it to fit right.

Here is what a measurement chart looks like with 13 samples to get the right fit.

Ok, you’ve nailed the fit! You are (almost) ready to make these damn pants!

Sizing

But first, you must grade them. Sizes! One of the things that make people feel crazy. why am I a size XS and a XL depending on the brand? True story. We get it.

When you create “grade” , which is a sizing rule for your garment, each measurement on the garment scales up or down by the rule you create. For example, if a waistband measurement increases or decreases by 2 inches per each size, XS - XL.

For a longer conversation about sizing you can read our blog post here, where we interview Jerry and Teri about sizing.

Manufactoring

Off to manufacturing. Here we choose Suuchi.

Since we were curious to expand the life experiences reflected in workwear, in-kind, we wanted our manufacturing to reflect that vision, as well.

Globally, no continent exceeds 38% of women in senior level positions. Women are over represented in support functions like administration, and are under represented in operations, profit and loss, and research and development*( sight below). We are not looking to fund a system that profits off women working low wages with no upward mobility.

There are many Asian and South/Central American factories operating ethically, taking care of workers, and generally doing the right thing. We envision properly vetting and using international markets as we grow. Many Asian factories are the most technologically advanced when it comes to certain aspects of garment construction - down jackets come to mind.

To start, we chose the United States for low minimum orders, confidence in our labor laws, and participation in our local economy. Supporting the local manufacturing infrastructure contributes to the overall success and health of rebuilding and advancing manufactoring in the united states. This is important to us. This system will help more women and all entrepreneurs to bring their visions to life. innovative products that will solve problems for their communities.